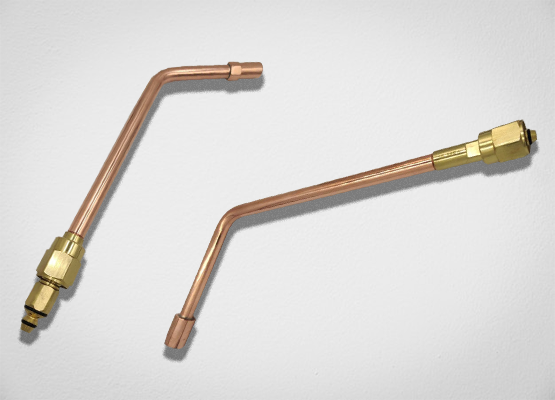

Heavy duty nozzles have thicker walls, likewise as thicker insulators, and are designed to be used in applications ranging amps. thanks to their heavier construction, these nozzles resist heat better than standard varieties. Standard nozzles tend to own a thinner wall and are better for amp applications. Slip-on nozzles are quite prevalent within the industry, compared to thread-on nozzles that require to be twisted to put in, and that they offer the advantage of having the ability to alter over more quickly. Nozzles are typically available in brass or copper. Brass nozzles tend to resist spatter well and are good for lower-amperage applications (100 to 300 amps), whereas copper nozzles are better for high-amperage applications (above 300 amps) or for those with longer arc-on time. For high-amperage water-cooled applications, there are nozzles available that circulate coolant round the nozzles. Our organization has successfully expanded its business within the market attributable to the offered elevated quality array of Welding Nozzels.